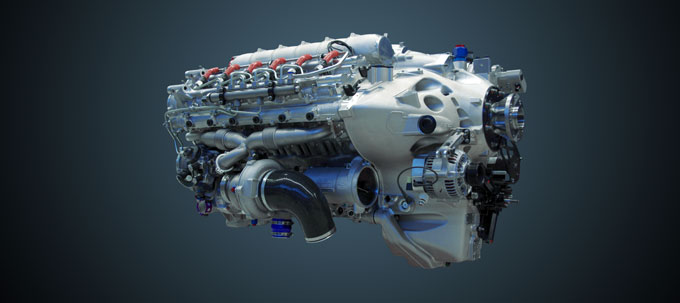

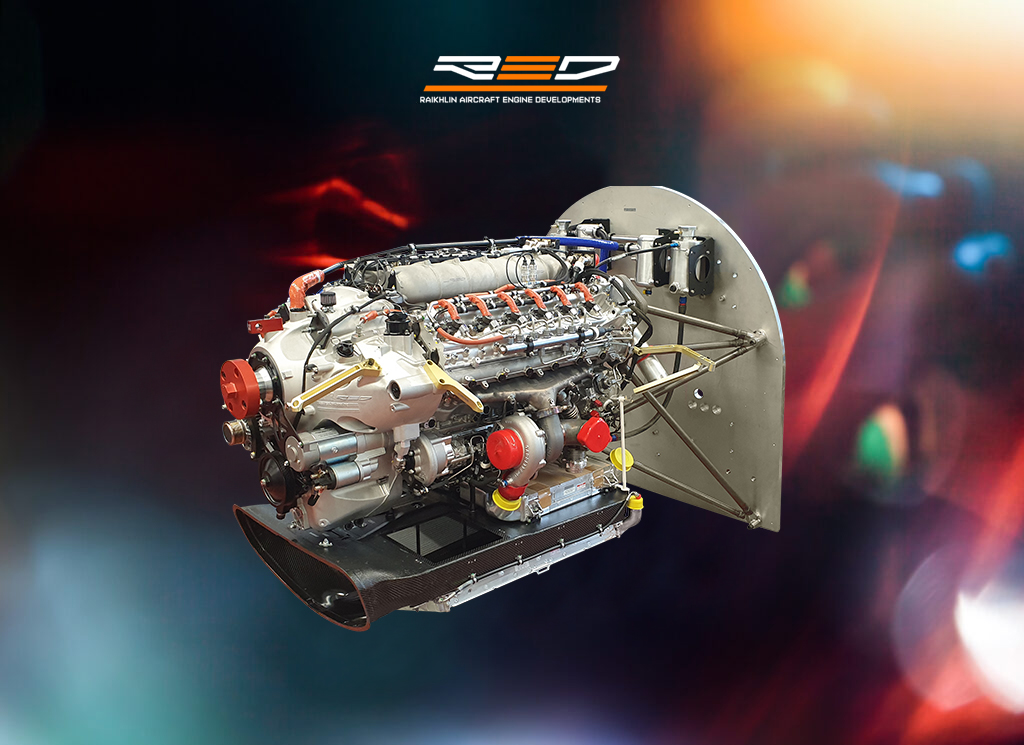

The RED A03 is a lightweight, all-aluminium, compression-ignition, internal combustion 12-cylinder engine in 80° V configuration with two six-cylinder banks capable of independent operation.

Key Features

- High safety level & Redundancy Concept with 2 independently operating cylinder banks, independent circuits for each engine bank

- FADEC, single-lever powertrain control, DAL-B, DO-254 and DO-178B compliant

- High efficiency and low fuel consumption at partial engine load, transient and hot & high conditions

- Very good altitude performance

- Designed for manufacturability and ease of maintenance

- Type Certified at EASA TC.E.150 and FAA.

Application Fields

RED engines are qualified for all categories-classes-types of CS-23 and CS-27 aircraft, which are supposed for Utility, Commuter, Aerobatic or Agricultural Application. The RED A03 can potentially provide a best-fit for Helicopters, Auxiliary Power Units (APUs), Hybrid Airships and Hybrid-Electric Aviation

Maintenance Solution

The engine is equipped with modern instrumentation to allow precise control of the engine health status. The FADEC is measuring, processing and storing engine data and providing all the required information to the operator and service personnel.

RED aircraft develops its own tools to access the engine data and to support the on-condition maintenance strategy so that the operator can benefit from

- minimized unscheduled downtime

- supports early maintenance decisions

- increasing the operation safety while having a detailed diagnostic and failure prediction in advance

- giving the engine performance feedback

- optimized scheduling and planning of the spare components or spare engines needed

- financial benefits and reduced maintenance costs

Key Advantages

Compared to piston engines

- Certified to use aviation kerosene, Jet-A1

- Significantly higher continuous and maximum take-off power rating, than other piston engines on the market

- Potential increase of aircraft payload, maximum operation speed and range

- Potential shorter runway & on-route climb time

- Better hot & high performance

- 20-40% lower fuel consumption, positively impact the fuel operation costs

- Digital engine control (FADEC) certified to HW/SW DAL B standard

Compared to turbine engines

- Significantly better fuel efficiency and result in reduction of fuel operation costs

- Potential increase of maximum flight range, due to much lower fuel consumption

- Even more efficient engine operation at lower altitudes

- MRO cost reduction

- Potential to use shorter runway, due to non-existing spool-up time

- Generally better hot & high performance, compared to non-derated turbines

- Lower noise and exhaust gas emissions